Laser Marker's New Rotary Workholding Enables Etching on Opposite Sides

ANCA's AutoMarkX is an automatic stand-alone laser marking station replacing manual and labor-intensive processes.

The AutoMarkX is AIMS Ready, which means it can be used as a standalone machine but could be easily integrated to your lights out, unmanned AIMS manufacturing cell with automatic pallet transfer using AutoFetch robot.

The machine eliminates the need for manual laser marking which is a repetitive and labor-intensive job which could be automated and therefore saving you money. By avoiding manual handling, tool quality is protected by eliminating risk of chipping.

AutoMarkX accepts up to two full pallets of tools, which means you can mark a large batch of tools unmanned.

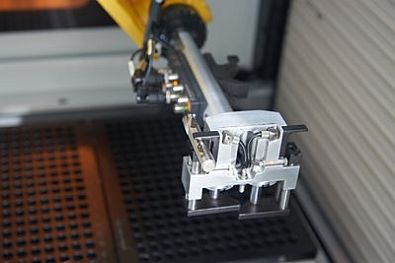

Flexible marking means the message could be etched on a single side of the shank or, using the AMX's new rotary workholding on opposite sides of the shank as well as at the end of tool. This new feature will be demonstrated for the first time at IMTS.

This latest laser marking option is particularly useful for applications where a unique tool identification code (e.g. Datamatrix) needs to be etched on the tool. Codes like Datamatrix are usually etched on the shank where they risk the exposure to excessive surface wear, rendering them unreadable. The end of tool is the best location to etch this type of code to overcome this issue.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy